(R)evolution in 3D printing? = Possibility to change the nozzle even cold

- 3. 12. 2021

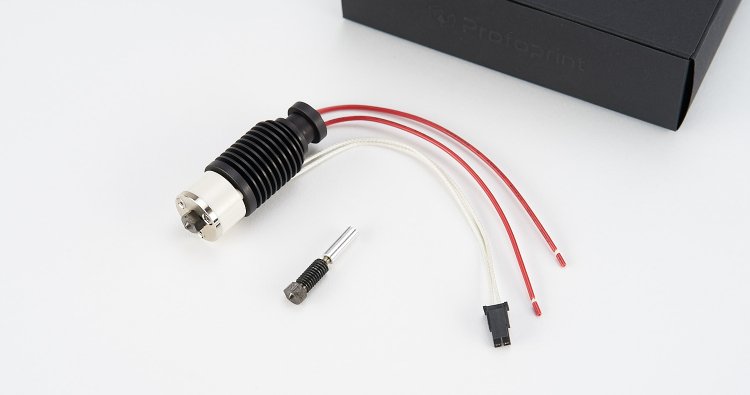

The ability to change the nozzle even cold, lower consumption or better filament melting. We have developed the Raptor Hot-End to take the most common hotend problems away from 3D printers. And there's no shortage of them.

Nozzle change even when cold

Perhaps the biggest pain of conventional hotends - if you want to remove the nozzle to replace or clean it, you have to heat the entire hotend first. And then you gently hold the heating block with one wrench while the other even more carefully releases the nozzle.

The Raptor Hot-End, on the other hand, allows you to remove the nozzle cold, so there's no risk of getting burned while working. You don't even need a wrench, you just remove the nozzle by hand. Thanks to the sliding coating of the copper nozzle, you can then remove any baked-on filament residue in seconds.

A neck that is many times narrower than normal

The "neck" is probably better known to printers as a thermal bridge or heat break. This component connects the cool part of the hotend, where the filament cools, to the warm part of the hotend, where the filament heats and melts. It is through the heat break that much of the heat is transferred to the cool part, which is why common hotends are equipped with a massive heat sink and fan. The Raptor Hot-end has a much narrower heat break due to its design - 0.15 mm compared to the conventional 0.5-0.3 mm - so the heat transfer is many times smaller.

It reaches temperatures of up to 500 °C when melting

The heating blocks of conventional hotends are made of aluminium and can handle temperatures of around 290 °C at most. So if you are printing from filament that only melts at very high temperatures (e.g. polycarbonate), printing is tedious and technically demanding.

In contrast, the Raptor Hot-end with its patented heat element with zirconia ceramic shielding and 60W ceramic heating ring can reach temperatures of up to 500 °C. This easily melts all common filaments and yet does not emit too much waste heat into the surrounding area.

Lightweight and compatible with all common printers

When designing the Raptor, we also played with the details. For example, the hotend is 20% lighter than standard hotends, so it doesn't weigh down the 3D printer as much and extends its life. The lighter weight also allows for faster printing. The hotend without the wiring weighs 40 grams.

During the development process, we repeatedly consulted and tested our Hotend with researchers at the Innovation Center, which is part of the Faculty of Electrical Engineering (RICE) at the University of West Bohemia in Pilsen. The Hotend is thus tested, and moreover compatible with all common printers such as Prusa and others.